Laser Welding & Brazing Inspection

To improve visual weld quality, one must begin with determining the joining processes’ capability to produce good welds day after day even with the inherent variability common in manufacturing plants. The inspection systems can help quantify what this variation is. After improving the process as much as possible, the inspection system is then used to monitor the ongoing quality.

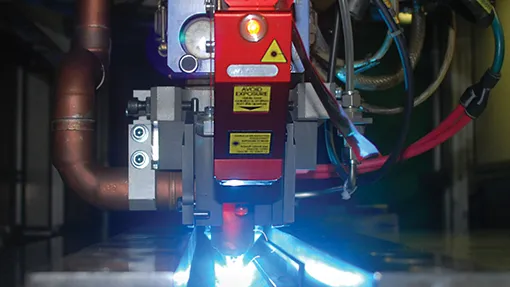

LAS-SCAN/MICRO™

The LAS-SCAN/MICRO™ system is composed of a 3D laser camera, a 2D color video camera, an industrial control unit and an inspection software package. SERVO-ROBOT provides a choice of several 3D laser-camera models adapted to the application, the inspection requirements, the access to the part to be inspected, etc. The LAS-SCAN/MICRO™ system can be interfaced to any special purpose machine or welding robot used today.

Image courtesy of Maser Engineering