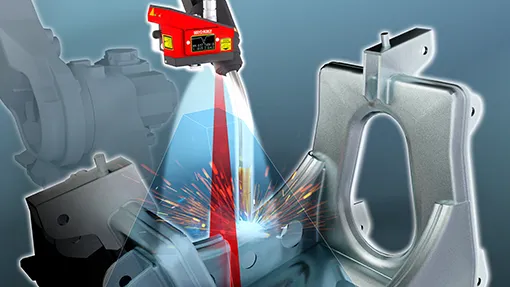

Arc Seam Finding

Seam Finding, often called Joint Finding, is the process of locating the seam using one or more searches to ensure the weld bead is precisely deposited in the joint by shifting the robot or machine program path prior to welding.

QUICK-SCAN™

The QUICK-SCAN™ is a compact and cost efficient laser-vision system designed for seam finding, joint fit up monitoring, 3D program shifting, welding inspection, and teaching. It includes high-speed 3D robotic mapping capabilities to generate precise points cloud. The QUICK-SCAN™ is used for applications that require pre- and post process measurements and inspection while keeping the overall footprint as small as possible.

QUICK-SPOT™

Robot friendly laser range measurement system 10 times faster and 5 times more accurate than touch sensing. Features and benefits include: designed for Easy Robot Integration, resistant to the Harshest Industrial Environments, compact Design, IoT Ready Technology and applicable to Collaborative Robots.

i-CUBE-T™

The i-CUBE-T™ is an advanced integrated hybrid sensing system for universal control of industrial robots. i-CUBE-T™ gives optical precision to industrial robotic processes and its rugged design and powerful

on-board control electronics make it ideal for industrial environments such as welding, cutting, handling, and inspection.