Arc Weld Inspection

To improve visual weld quality, one must begin with determining the joining processes’ capability to produce good welds day after day even with the inherent variability common in manufacturing plants. The inspection systems can help quantify what this variation is. After improving the process as much as possible, the inspection system is then used to monitor the ongoing quality.

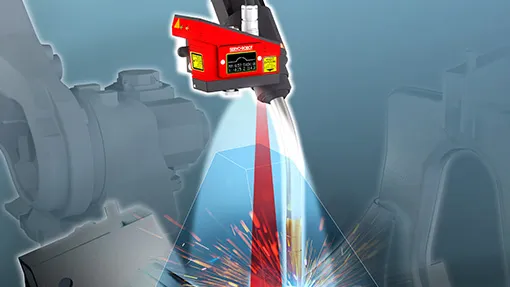

ARC-SCAN™

Measurement system for arc welded components. ARC-SCAN™ is the latest SERVO-ROBOT Robotic Quality Management System that measures joint characteristics and continuously verifies weld quality. ARC-SCAN computes geometric characteristics of weld beads, identifies geometric defects, and helps to rapidly analyze potential causes.

i-FACT MICRO™

The i-FACT MICRO™ system is the latest SERVO-ROBOT robotic welding management system available on the market. i-FACT MICRO™ automatically digitizes parts, joints and welds in order to verify compliance with the customer’s specifications and standards.

i-FACT MICRO™ provides real-time go/no go information to automatically evaluate weld quality based on the manufacturer’s own criteria which are freely programmable into the system via a user-friendly human machine interface.