Arc Seam Tracking

Seam Tracking, also known as Joint Tracking, involves real-time tracking just ahead of where the weld is being deposited. This allows for not only robot or machine trajectory shifts, but also adaptive control such as adjustments to voltage, wire feed, or travel speed to change weld bead formation.

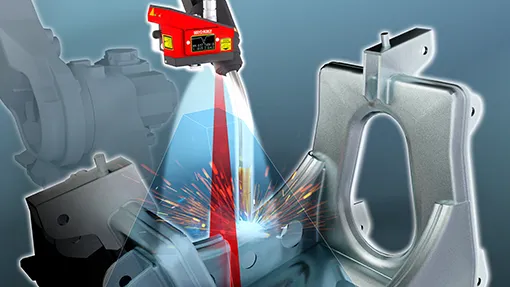

AUTO-TRAC/E™

AUTO-TRAC/E™ is a complete 3D laser-vision system for joint tracking and adaptive process control designed for special purpose welding machines. Fully integrated standard system which includes laser camera, control unit, actuators, teach pendant, and ready-to-use software. AUTO-TRAC/E™ is designed to operate on any joint preparation ranging from sheet metal to heavy plate complex grooves.

Image courtesy of Advanced Welding Methods

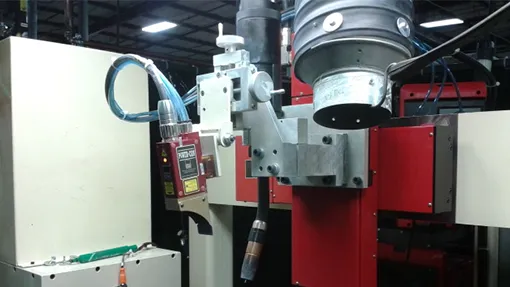

AUTO-TRAC/PLC™

AUTO-TRAC/E™ is a powerful yet compact seam tracking system for hard automation that includes a 3D laser-vision camera and software to provide numerous functions including joint vision analysis, two axis trajectory calculation, optional adaptive control and others. Up to two axes (actuators) can be controlled by the PLC interfaced with the vision system via ProfiNet I/Os.

QUICK-SCAN™

The QUICK-SCAN™ is a compact and cost efficient laser-vision system designed for seam finding, joint fit up monitoring, 3D program shifting, welding inspection, and teaching. It includes high-speed 3D robotic mapping capabilities to generate precise points cloud. The QUICK-SCAN™ is used for applications that require pre- and post process measurements and inspection while keeping the overall footprint as small as possible.

POWER-TRAC 4.0™

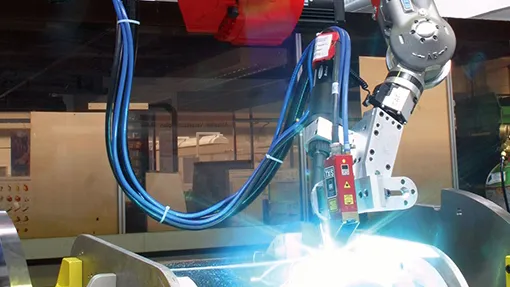

POWER-TRAC 4.0™ system which is the product offered by SERVO-ROBOT for robotic real-time seam tracking, offline seam finding and adaptive control. In seam tracking mode, the tool trajectory is modified continuously to compensate for part position variation. In seam finding mode, parts and/or features position is measured first to offset the robot path accordingly.

Image courtesy of REIS Robotics (China) Co., Ltd.