May 2010 – Optimize Your Welding Applications While Immediately Full-Proofing Your Production Operations So No Substandard Products Leave Your Plant.

Welds produced at several meters per minute cannot be inspected efficiently by the human eye, which is why special laser-cameras have been designed to verify the geometric profile of the bead and identify defects. Laser vision systems have been found to be the most repeatable and reliable technique for the inspection of components made in high volume continuous production. A key point is that the laser vision inspection systems provide quantitative data which can be used to determine process capability, whereas other products on the market cannot.

Using the latest image processing technology, SERVO-ROBOT laser vision systems can be used for inspection and also can be combined to seam tracking in some cases. Three potential inspection scenarios are available:

One laser-camera for both tracking & inspection:

System can track the joint during welding and then after welding is completed, it can inspect the weld geometry and detect defects at a speed four times faster than the speed used for welding.

Two laser-cameras for both tracking & inspection:

One laser-camera measures and tracks during welding while the second laser-camera, mounted behind the torch, inspects the completed weld.

One laser-camera used only for inspection:

This system can either be integrated in the welding cell or as a standalone system located after the stations where welding was done.

Inspects Weld Shape/Geometry

SERVO-ROBOT 3D laser vision systems offer the high resolution, speed and imaging quality required to accurately measure the weld surface. The system can automatically compare the results to the tolerances that had been previously entered in the system and provide immediate Go/No-Go feedback.

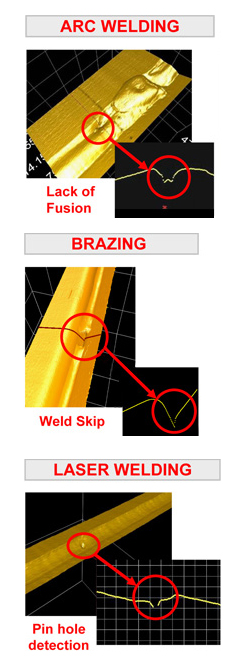

Detect Weld Defects

SERVO-ROBOT systems offers the possibility to check the weld geometry as well as the detection of weld defects such as excessive undercut, burn through, excessive porosity, spatter, etc. This unique capability is due to the advanced imaging technology used in SERVO-ROBOT inspection systems.