NEW PRECISE 3D LASER-VISION SYSTEM FOR MULTI-PASS WELDING AUTOMATION

The new SERVO-ROBOT DIGI-I/Z™ laser vision real time seam tracking system has several new capabilities that address the needs associated with heavier section welding which is increasing in demand and also the desire for more real time weld process monitoring. Specifically the DIGI-I/Z™ system includes:

- The ability to optimally focus the camera to perfectly track the root of large groove (narrow groove, narrow gap, deep groove) joints by precisely placing the wire in the required location to avoid defects that can commonly occur like lack of penetration and lack of fusion, and the ability to view the complete joint cross section through the clever optical design of the laser camera.

- Conversely, when the welding of the upper levels of the large groove joint needs to be done, the camera can make use of both its large field of view and its very high accuracy focused second field of view. This makes it possible to optimize the individual bead placement to achieve excellent weld quality and to minimize wasteful over welding.

- Real time process monitoring allows anyone to look at the weld and the joint area to verify the weld is progressing as planned. This is done via a built-in color video camera as well as real time monitoring of the joint variability.

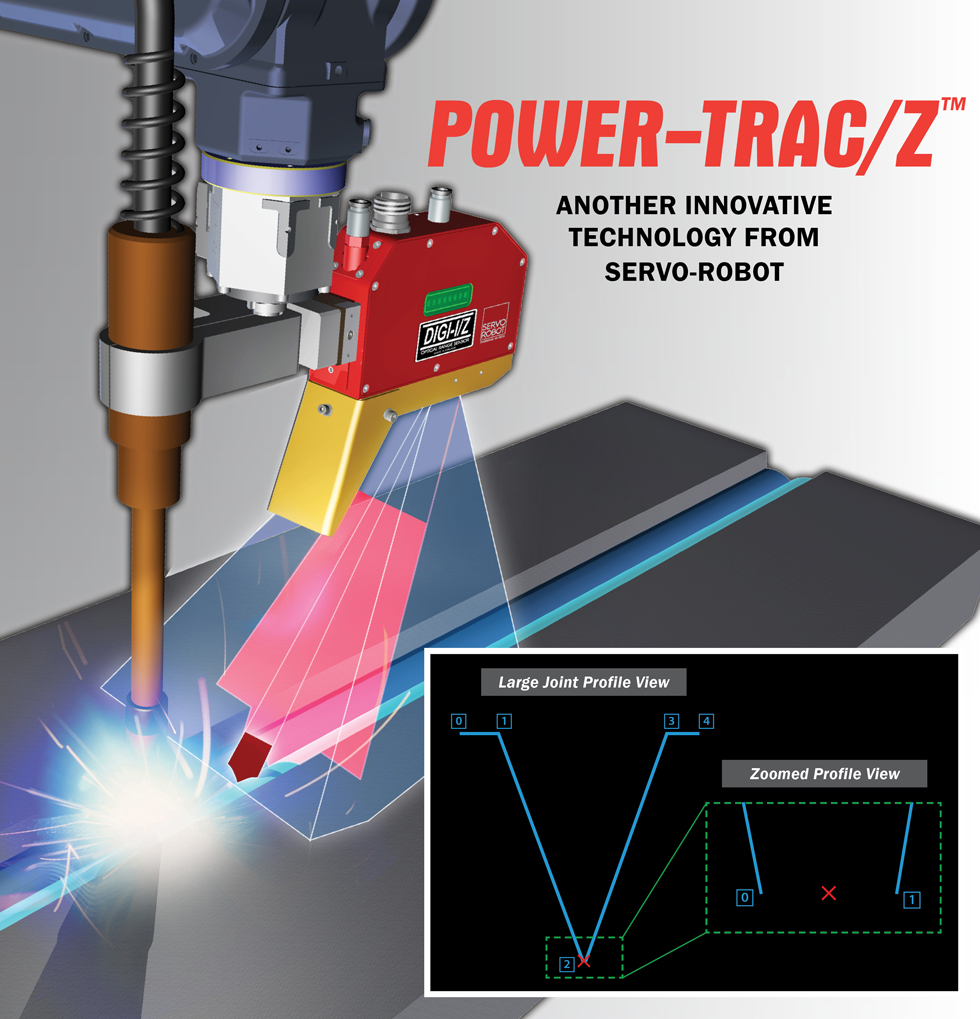

- To complete the process, the POWER-TRAC/Z™ can also be provided with a complete weld inspection system that can be used to go back over the finished weld to make sure it meets the quality standard in place.

- The programming and process monitoring have become much easier thanks to the Tablet HMI being used.

The POWER-TRAC/Z™ will set the standard for all new seam tracking systems targeted at the heavy welding requirements associated with growing markets like heavy pipe, power plant vessels and other large structure weldments.