SERVO-ROBOT laser-camera systems are very effective in a variety of shipbuilding welding applications including welding stiffeners, panel plate splicing, modular block construction, and submarine hull butt joining. We strive to improve quality, productivity, efficiency and save you money.

SERVO-ROBOT Systems

AUTO-TRAC™ is the right product to achieve success in automated ship panel welding. This system offers real-time seam tracking and adaptive control for fixed automation across all welding industry applications.

ROBO-TRAC™, in conjunction with all standard articulated and gantry style robots, is also available to perform seam tracking and adaptive control.

Weld inspection systems are also available from SERVO-ROBOT.

Examples of Shipbuilding Applications:

Ship hull panels

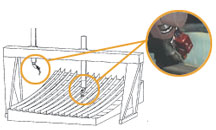

Ship hull flat panels are joined in the factory before assembling the ship modules. For many years, this has been done using automatic welding machines mounted on gantries.

At Right: Submerged Arc Weld (SAW) panel line with a square butt weld joint utilizing the AUTO-TRAC™ seam tracking system.

Typical Situation Today:

● Submerged Arc Welding used-both single and multiple wires.

● High deposition rates often result in over welding.

● Slow travel speeds.

● Thin plate welding typically uses square butt joints.

● Heavier plate welding can use V, Y, J and U joints.

● Constant monitoring of the process by the operator is required.

● Manual adjustment of the torch position is needed resulting in operator fatigue.

Benefits of utilizing Servo-Robot Laser Vision:

● One operator can supervise two or three machines at the same time.

● Reduced level of skill necessary to operate.

● Improved weld quality due to accurate torch positioning.

● Increased travel speed achieved because wireposition is always in joint.

● Reduced over-welding saves on consumables.

● Automated multi-pass welding sequence management for thick plate applications.

Ship stiffener WELDING

Ship panel stiffeners are typically welded with the use of large gantries. Touch probes are the traditional way to ensure the correct position, but they are inconsistent, require constant maintenance and cannot be used on certain joint types.

Ship panel stiffeners are typically welded with the use of large gantries. Touch probes are the traditional way to ensure the correct position, but they are inconsistent, require constant maintenance and cannot be used on certain joint types.

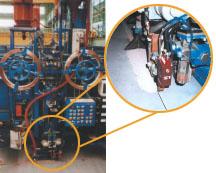

At Right: Illustration of Tandem Welding Robots on a Gantry welding panel stiffener system. Inset: A ROBO-TRAC™ seam tracking system measuring root gap to allow adaptation of welding parameters.

Typical Situation Today(when robots are used):

● GMAW/MIG used.

● Mechanical Touch probes.

● Large gantry with two articulated robots.

● Robots setup using off-line programming.

Benefits of utilizing Servo-Robot Laser Vision:

● Faster travel speed achieved.

● Simultaneously controls the welding parameters.

● Easily reprogrammed for job changes.

● Save money on consumables by reducing overwelding.

Submarine hull butts

Submarines are built up from cylindrical shaped round modules that need to be joined utilizing “hull butt” groove joints. The material thickness is typically 50mm or greater which means over 30 passes are used. Laser vision is used to not only track the joint but to allow real-time path planning, adaptive processing and process control to take place. This greatly improves the weld quality resulting in reduced repair.

OTHER techniques & Related Applications:

OTHER techniques & Related Applications:

● Portable Robot (Pictured at right)

● Laser Welding

● Laser Hybrid Welding

● Pipe Welding