SERVO-ROBOT laser vision systems are very cost-effective and for 30 years have been successfully applied in tank & vessel welding applications, including circumferential joints, longitudinal joints and attachment welding.

In specific water heater tank production plants, the leakage rate pre-repair due to welding defects is now less than 0.5% after SERVO-ROBOT precise laser tracking systems were installed. Uptime was increased due to minimal equipment issues and a reduced need for maintenance to be performed. The manpower was reduced by two-thirds in many cases because now one operator can oversee several systems simultaneously. Not only was the welding quality and productivity improved, but costs related to weld repair and scrap were remarkably decreased. At the same time, high reliability and durability saved more money for customers.

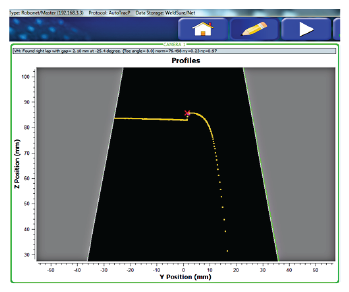

The stainless steel or aluminum fuel tanks often have square or more complex shapes. With articulated robots, SERVO-ROBOT laser vision seam tracking systems are successfully applied for welding stiffeners inside the tanks as well as the end caps of the tanks. In Europe (Holland, Sweden, Switzerland and France), North America and China, a robot with a SERVO-ROBOT laser tracking system has already become a standard solution for welding these complex shaped tanks, e.g. truck gas tank, LNG tank, food tank, cement mixer, liquid transport tank etc.

Many SERVO-ROBOT laser tracking systems installed over ten years ago are still running on product lines today attesting to their ruggedness and ease of use as well as their ability to save money, increase production rates and improve overall quality.